|

Guangzhou C&H Medical Co.,Ltd.

|

Medical Oxygen Manifold Products For Medical Central Gas Equipment

| Price: | 500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU;Cash |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Medical Gas Manifold System

Medical Gas Source Equipment with Cylinders

Medical Gas Regulators System

For Medical Gas Pipeline System

Customized

Medical Oxygen Manifold Products For Medical Central Gases Equipment

More details~

Before, the medical gases in hospitals are stored and supplied by separated medical gas cylinders. The separated medical

gases (including oxygen, compressed air, nitrous oxide, carbon dioxide, etc.) cylinders are put in the operating theatres,

wards, etc. By this way, it is not so convenient and safe for medical staff to use.

Now, more and more hospitals adopt the Medical Gas Pipeline System for medical gases supplying. With Medical Gas

Pipeline System, it achieve to supply different medical gases uninterrupted and safely

With Medical Gas Pipeline System, the oxygen in cylinders is not the oxygen source any more. However, as a back-up

oxygen source, Oxygen Cylinders (with pressed oxygen gases inside) controlled by medical gas manifold system is still a

necessary equipment for medical oxygen supplying in hospitals. Also, for some small hospitals, Medical Oxygen Manifold

System is a more economical medical source equipment than the Medical Oxygen Generator System.

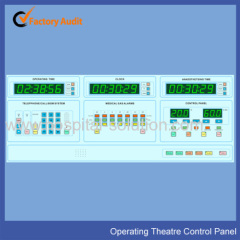

Function of a Manual Dual Lines Medical Oxygen Manifold System

1.To connect several different medical oxygen cylinders together: the Manual Dual Lines Oxygen Manifold System

connected and manage several pieces of oxygen cylinders, to collect the medical oxygen gas in different oxygen

cylinders and then supply to medical oxygen pipeline;

2. To regulate medical oxygen gas pressure: medical oxygen gas in cylinders is in a high pressure (usually the initial

pressure is 15MPa). This high pressure oxygen gas can not be supply to patients or other medical equipment directly.

Before it supplied, the pressure must be regulated to a much lower one. The Manual Dual Lines Medical Oxygen

Manifold System achieve to regulate the oxygen gas pressure;

3.To manage oxygen cylinders in different lines: medical oxygen cylinders are connected with the Manual Dual Lines

Oxygen Manifold System's different lines. Usually, these two lines are controlled separated, and they do not supply

medical oxygen gas one the same time. After the medical oxygen cylinders in one line are empty, users can shut off

this line, and turn on another line. The empty oxygen cylinders can be discharged and to be refilled. To repeat these processes can ensure uninterrupted medical oxygen supplying to hospital oxygen pipeline

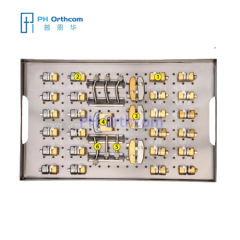

Parts of a Manual Dual Lines Medical Oxygen Manifold System

(1) Medical Oxygen Regulators: to regulate oxygen gas pressure;

(2) One-Way Valves / Non-Returning Valves: to avoid oxygen gas return to cylinders;

(3) Pressure Gauges: to show oxygen gas pressure in different section;

(4) Pigtails / Stainless Steel High Pressure Hoses: to connect oxygen cylinders;

(5) Pipes: to connect different parts;

As a manufacturer of medical gas pipeline system equipment and materials manufacturer, Ningbo JianZhiKang Medical

Equipment Co., Ltd. produce and supply different models of Manual Dual Lines Medical Oxygen Manifold Systems.

General Features

1. Operating and line regulators provided with relief valve;

2. Pressure switch with dry contacts pressure sensor to indicate reserve in use;

3. One-Way Valves / Non-Return Valves;

4. Customize for different quantity of oxygen cylinders;

5. Customize for different standards of oxygen cylinder valves;

Wall Type Cylinder Brackets (to be ordered separately);

Specifications:

1. Safe Input Pressure: 20.0MPa;

2. Service Input Pressure: 15.0MPa;

3. Service Output Pressure: 0.4~0.8MPa adjustable;

4. Service Output Flow Rate: ≤120Nm3/hour;

We also produce and supply Manual / Automatic Medical Gas Manifold Systems for Nitrous Oxide, Compressed Air,

Carbon Dioxide, etc.

Medical Oxygen Manifold System

What do we supply:

We produce different standards of Medical Gas Outlets for O2, Vacuum, Medical Air, Compressed Air, N2O, CO2, AGSS, etc.;

The standards of Gas Outlets include: British Standard, German Standard, French Standard, South African Standard, Metric Standard, Ohmeda Standard, DISS Standard, Chemetron Standards, Puritan-Bennett Standard, etc.;

What advantage do we have:

1, Original Manufacturer: all the Gas Outlets and the Gas Outlet Adapters are produced by our own factory;

2, Certificate: ISO13485 (issued by SGS), CE (issued by SGS);

3, Producing Equipments: the producing equipments for the Gas Outlets include CNC (8 sets), Stamping Machine (10 sets), Automatic Welding Machine (2 sets), Metal Treatment Set (1 set, large scale), etc.;

4, Material: all the products are made of original material;

5, Quality: all parts are produced by ourselves with strict quality controlling;

6, Cost: we have competetive cost advantage because of the scale economy;

7, Perfect appearance of the gas outlets and adapters;