|

Guangzhou C&H Medical Co.,Ltd.

|

Hospital Oxygen Plant as Medical Central Oxygen Equipment

| Price: | 8000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU;Cash |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Mini oxygen generator plant

PSA Oxygen Generator System

For Medical Gas Pipeline System

Oxygen Producing Capability: 3~300c.b.m./hour

Hospital Oxygen Plant as Medical Central Oxygen Equipment

WHAT IS PSA

PSA (Pressure Swing Absorption) is one of the most popular methods used for the commerical production of Oxygen gas. PSA technology is suited to small and medium sized productions needs.

The PSA process cosists of pumping air through a bed containing a filter medium (Molecular Sieve) that preferentially absorbs nitrogen, while allowing oxygen to pass through unrestricted. Eventually, the filter bed becomes saturated with nitrogen and must be regenerated. It is the feature of the filter media that nitrogen is absorbed at pressures at 0.7MPa (7Bar) and is desorbed at atmospheric pressures. The desorbed nitrogen is then flushed away by a proportion of the purified oxygen.

This system of CH-6M3/H C&H PSA Oxygen Generator System (PSA Oxygen Generator & Filling Equipment) is a special customized oxygen genertor system for Medical Oxygen;

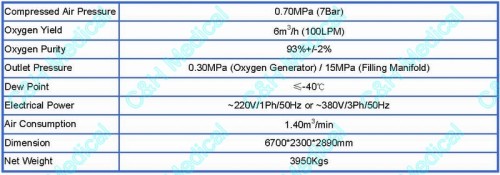

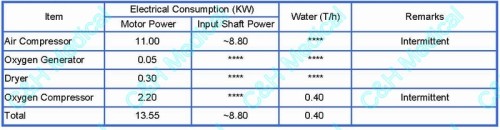

PSA Oxygen Generator System Technical Index

PSA Oxygen Generator System Consumption

CHO-6M3/H C&H Medical PAS Oxygen Generator System Technological Processing

Medical PSA Oxygen Generator System Parts:

Air Compressor

To supply air as the material for PSA. Also, it pressurize the air to 7Bar pressure;

Compressed Air Purification System

1, High Efficiency Filter: Compressed air pass through the High Efficiency Filter, to remove most oil / water in air;

2, Precision Filter: Compressed air pass through the Precision Filter, to remove oil / watre; After, the content of oil / water less than 0.1ppm;

3, Refrigeration Dryer: To make compressed air dew point to 8-10ºC;

4, Micron Oil / Water & Particle Filter: to make oil / water content less than 0.01ppm, particle content less than 0.01μ;

5, Active Carbon Filter: To oil / water content in compressed air less than 0.003ppm;

Oxygen Generator

The processed compressed air comes in the absorbing tanks. In tanks, the nitrogen is absorpted by Molecular Sieve, and the oxygen is preserved. In this system, there are two pcs of absorbing tanks. One is used for absorbing nitrogen, another is used for regerating. These two pcs of absorbing tanks are controlled by PLC automatically to make them work alternately.

Oxygen Filling Manifold System

To pressurize the oxygen to 15MPa and then fill it into the oxygen cylinders.

As a professional manufacturer of Medical Equipment for Medical Gas Pipeline System, Guangzhou C&H Medical Co., Ltd. supplies the PSA Medical Oxygen Generator System for Hospital Gas Pipeline System which:

Oxygen Producing Capability: 3~300m3/hour;

Oxygen Purity: 91~95% (93% +/- 2%);

With / Without Oxygen Pressing and Cylinders Filling Manifold System

For exporting, we have exported our Medical PSA Oxygen Generator System to more than 10 countries.

For more details and for installing engineering, please contact us.

Why do you choose us as your supplier partner

1, Professional manufacturer: in Medical Gas Pipeline System Industry since 2004; Also, we have Medical Gas Pipeline System Engineering Company in China; So, we know our partners' and hospitals' requesting well;

2, High Quality Products: with ISO13485:2003 / ISO9001:2008 Quality Management System; The quality has been confirmed by repeated orders from most importers;

3, Good Price: Mass manufacturing + reasonable margin make the products has good advantages for price;

4, One-Stop Supplying: we supply equipments for the whole medical gas pipeline system; Importers do not need to source and compare different equipments from different suppliers, and do not need to afraid of the compatibility from different factories;

5, Exporting Experience: more than 7years' experience for exporting; We know many special demands of different countries' custom, different shipping companies, to help partners to reduce business cost;

6, Real manufacturer: passed ALIBABA.COM factory Factory Audit (Production Audit Report No.201103220000753_1-P, you can download and check it in our website), with ISO13485:2003 / ISO9001:2008 / ISO14001:2004 / GB/T28001:2001 / CE 0120 certificates;

Any question pls contact us!